NIRAV CHEMICAL INDUSTRIES

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to NIRAV CHEMICAL INDUSTRIES

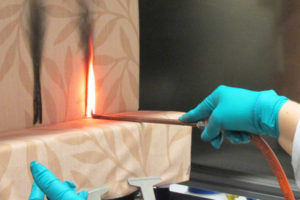

Hand Lay Up

The process is also called as contact molding or wet layup. It is the most commonly used and easiest method for the small and large reinforced polyester products. It has least Molding thickness is generally in the range of 2-10mm although there is no basic upper limit. The production number by this method is low, but it has low mold cost and least infrastructure requirement.

Filament Winding

Filament winding is used to make round parts like pipe, tanks etc. In this process resin impregnated strands of continuous glass fiber roving are wrapped around a mandrel by a machine. The machine can be computerized programmed. In this way continuous length of pipe can be produced with diameter range from 0.3 to 3.5 meter.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.